pico Plywood Contact

Contact Information

To learn more about our Plywood Products or discuss your project requirements, please reach out to us through the following channels.

wood's advantages

Table of Contents for the Article

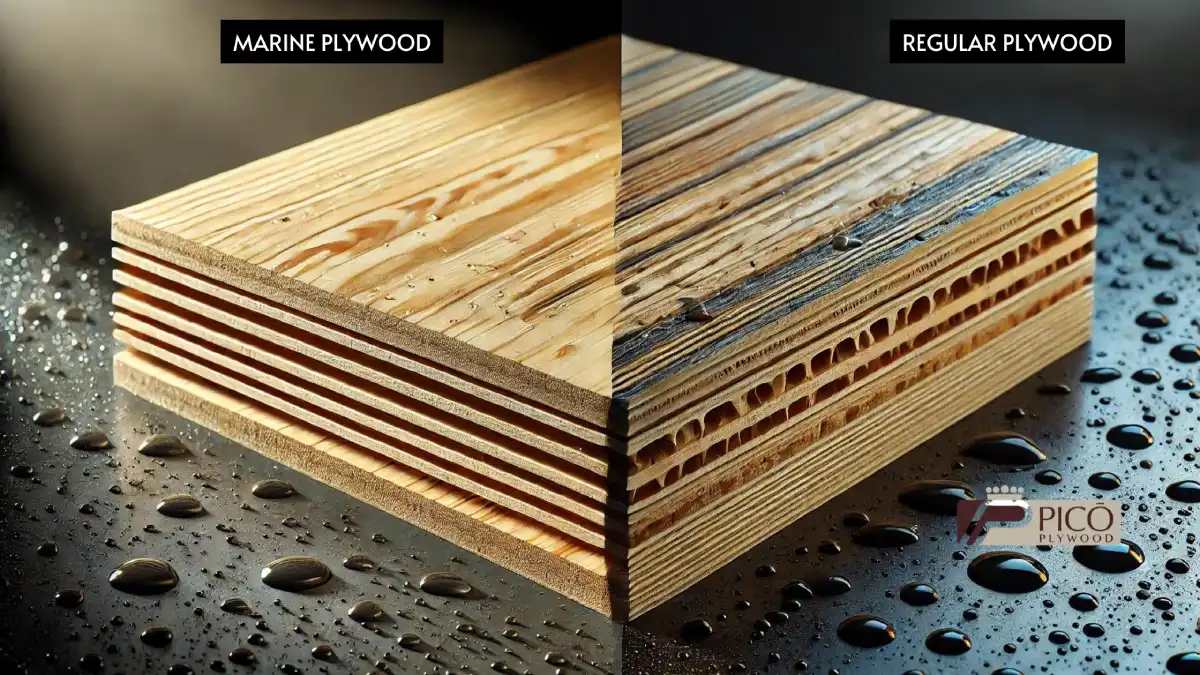

When it comes to woodworking, selecting the right type of plywood can make all the difference in the quality and longevity of your project. Two common types often considered are marine grade plywood and regular plywood. But what sets them apart? Understanding these differences can help you choose the right material for your specific needs, especially if you are working on a project that will be exposed to moisture or harsh conditions.

At its core, plywood is a material made by gluing together thin layers of wood veneer. These layers, or «plies,» are laid out with their grain running at right angles to one another. This cross-grain arrangement gives plywood its strength and durability, making it a popular choice in construction, furniture making, and many DIY projects.

There are many types of plywood, including hardwood plywood, softwood plywood, and specialized versions like marine grade plywood. The difference in each lies in the types of wood used, the glue, and how the material is treated.

Marine grade plywood is specifically designed for environments where the wood will be exposed to moisture and harsh conditions. It is constructed with the highest quality veneers and waterproof glue, ensuring that it can withstand the demands of marine environments like boats, docks, and other water-based applications.

Marine grade plywood is typically made from durable hardwood species, such as oak, mahogany, or Douglas fir. These woods are chosen for their ability to resist moisture and their long-lasting performance in wet conditions.

Regular plywood, while also made by gluing together wood veneers, doesn’t have the same stringent requirements as marine grade plywood. It’s often used in indoor projects or situations where the material won’t be exposed to high moisture levels.

Regular plywood can be made from both hardwood and softwood species, but the key difference is the quality of the veneers. While still strong, regular plywood may contain more voids and defects than its marine-grade counterpart.

Marine grade plywood is designed to be incredibly durable and resistant to environmental factors like water, humidity, and temperature changes. Regular plywood, though strong, doesn’t have the same level of durability, especially in wet conditions.

The most significant difference between the two types of plywood is their resistance to moisture. Marine grade plywood excels in wet environments, while regular plywood is more likely to warp, swell, or break down when exposed to water for long periods.

Marine grade plywood is more expensive due to its superior materials and construction. Regular plywood, on the other hand, is much cheaper and readily available, making it ideal for projects on a budget.

Marine grade plywood is the go-to choice for projects involving boats, docks, and other water-related structures. Its resistance to moisture ensures that it will last longer in harsh environments.

Regular plywood is perfect for indoor projects, such as shelving, cabinetry, or general home repairs. It can also be used in areas that won’t experience a lot of moisture, like walls or ceilings.

Highly durable, excellent moisture resistance, long-lasting.

Affordable, versatile, easy to work with.

Less moisture resistant, not suitable for harsh environments.

When comparing marine grade plywood and regular plywood, it’s clear that both have their strengths and ideal uses. If your project is in a wet or harsh environment, marine grade plywood is worth the investment. For indoor or dry projects, regular plywood offers a versatile and cost-effective solution. The choice ultimately depends on the specific needs of your project.

Regular plywood can be used for outdoor projects, but it should be treated or sealed to prevent moisture damage.

Marine grade plywood can last decades in the right conditions, especially when properly maintained.

For projects exposed to water or high humidity, the added cost is worth it for the durability and longevity.

Yes, though it’s typically overkill for indoor projects unless moisture is a concern.

Marine grade plywood will be stamped with a certification indicating its grade and will have no visible voids or gaps in the layers.

pico Plywood Contact

Contact Information

To learn more about our Plywood Products or discuss your project requirements, please reach out to us through the following channels.

Esta web utiliza cookies para que podamos ofrecerte la mejor experiencia de usuario posible. La información de las cookies se almacena en tu navegador y realiza funciones tales como reconocerte cuando vuelves a nuestra web o ayudar a nuestro equipo a comprender qué secciones de la web encuentras más interesantes y útiles.

Strictly necessary cookies must always be enabled so that we can save your cookie setting preferences.

If you deactivate this cookie we will not be able to save your preferences. This means that each time you visit this website you will have to activate or deactivate cookies again.

Esta web utiliza Google Analytics para recopilar información anónima tal como el número de visitantes del sitio, o las páginas más populares.

Dejar esta cookie activa nos permite mejorar nuestra web.

Please enable strictly necessary cookies first so we can save your preferences!